MiL

MiL: the beginning of the process

MiL testing involves using a mathematical model of a system component as the testing environment. This allows engineers to evaluate and validate the behavior and functionality of specific aspects of a system before the actual hardware implementation takes place.

Driving simulators have boosted the vehicle design with the introduction of human beings in the simulation loop. For a realistic functioning, the steering system must provide an accurate behaviour, since the hand wheel is a crucial human interface.

Despite a large diffusion of steering models, this paper deals with the creation of a specific solution for real-time applications, characterized by precise features as numerical stability and low computational cost.

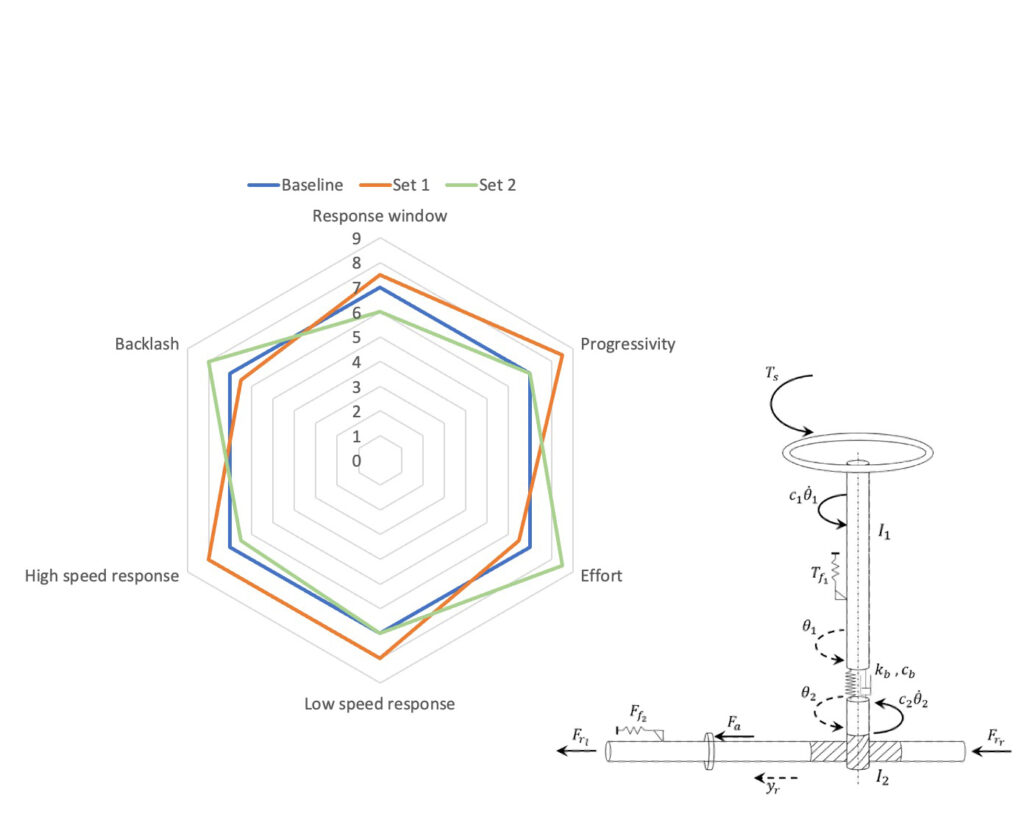

The mechanical model is composed by two DOF:

1. The first one composed by the: steering wheel, steering column and hooke joints

2. The second one is composed by the pinion, rack and tie rods.

The two masses are connected by the torsion bar modelled as a simple torsional spring and damper.

The HPS is modelled by a simple function in two variables which are the torsion bar torque and vehicle velocity plus a first order delay to approximate the system dynamic response.

# Superior understanding of the phenomena

# Deployment of the specification framework

# Easy and quick benchmark of different architectures

# Human-centred design from scratch with driving simulators

Case study: Real-time steering system model

Development of an Angle-Driven 2 DOF steering system model specific for real-time applications

# Model requirements:

- Accurate steering wheel angle to rack position relation

- Accurate power steering assistance modelling

- Friction effects properly modelled

- Real-time features

- High numerical stability

- Ease of parametrization

- Implementation at the simulator possible

# Modelled key phenomena:

- System elasticities

- Power steering effects

- Friction hysteresis

# Modelled components:

- Rack

Friction force, viscous coefficient, Stribeck velocity, inertia - Torsion bar

Stiffness, damping - Steering column

Friction force, viscous coefficient, inertia

# HPS Hydraulic Power Steering:

- Steady state curves

- Time constant

Case study: Real-time suitable steering system model

# Model validation: Objective Assessment

# Model comparison:

- Proving ground data

- 2 DOF Model

- 1 DOF Model

# Slow ramp steer ISO 4138:

- Constant velocity

- Constant slope steering wheel ramp profile

# Weave test ISO 13674:

- Constant velocity

- Constant sine amplitude

- Constant sine frequency

# Results

- High fidelity steer torque reproduction from low to high lateral acceleration

- On center stability

- Effective reproduction of hysteresis effects

- Accurate Steering wheel angle to vehicle lateral acceleration relation

Case study: Real-time suitable steering system model

# Model use: requirements allocation