How BBW actuators enhance vehicle development and performance

Traditional hydraulic braking systems have been a mainstay in the automotive industry for decades.

Yet, as vehicles evolve to support increasingly Advanced Driver Assistance Systems (ADAS) and Autonomous Driving, these systems reveal their limitations, particularly in terms of complexity, scalability, and integration with electronic control units.

Brake-by-wire technology marks a fundamental shift by replacing mechanical linkages with fully electronic control. This transition enables simpler and more streamlined architectures, improves system reliability, and allows seamless integration with modern driving functions.

For autonomous vehicles, for example, brake-by-wire is essential.

Without a human driver to press the brake pedal, a central computer must calculate the required braking force and send a target command to the system, which must execute it with precision and consistency. This level of control is simply not achievable with conventional hydraulic systems.

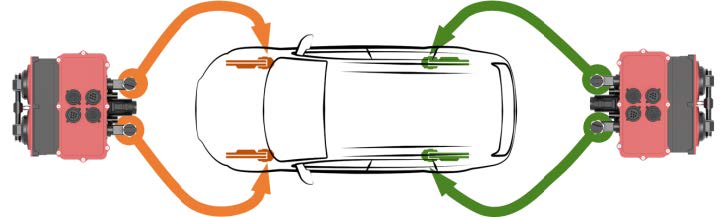

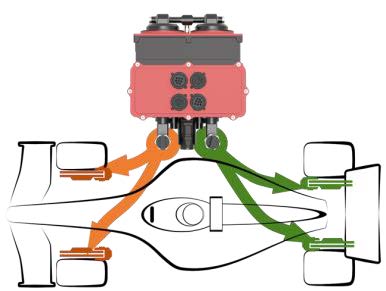

Meccanica 42’s Corner Brake Actuator (CBA) is designed to meet this challenge.

It allows independent control of each brake line, offering engineers the flexibility to manage braking at each corner of the vehicle. Whether used in advanced testing environments, modular system configurations, or high-performance platforms, CBA delivers the responsiveness and adaptability required by next-generation vehicles.